Eternal ephemera

Stanford ME203 Design and Manufacturing

Solo project, 3 months

Fall 2019

Instructor: David Beach

Skills:

Adobe Illustrator

Lasercutting

Plastic Thermoforming

Material Innovation

Rapid Prototyping

Prompt:

Create a product from initial ideation to sketches, iterate through prototypes, and manufacturing.

Approach:

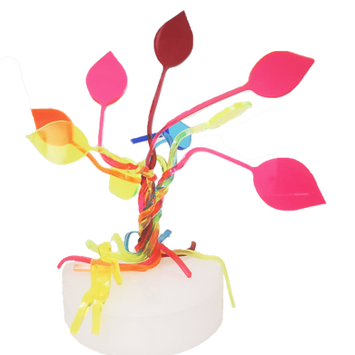

Create a tree sculpture out of sheeted acrylic plastic. Using the lasercutter and thermoforming methods, make a brittle material look soft and organic.

Additional constraints:

My manufacturing process was limited to the lasercutter.

Eternal flora

Plastic is everything. In the products we use everyday, our clothes, the paint on our walls, the cups we drink from, and in the food we eat.

I reimagined plastic at the root of what is life-giving to us --what more lifegiving than the trees that provide us with oxygen to breathe?

This project imagines and manifests plastic in one of its original forms: as a tree. The tree is symbolic of the organic biological matter fossil fuels once were millions of years ago, that now in this industrial age became processed into plastic material.

From its original biological form, to plastic sheet, to an organic mimetic acrylic tree, this project highlights lifecycles, calls attention to the material's lengthy and epic history, as well as pushes the material's boundaries in form, time, and space.

This artificial flora is borne of the industrial yet simulates organic curves and form. It contains within itself an artificial glow that must be replenished continuously to sustain its luminosity via sunlight or other source, but retains an alien fluorescence from within.

Leaves and trees grow and fall, but this object presses pause on the cycle of natural death and rebirth, freezing this moment into an almost immortal artifact -- plastic takes a long time to decompose, hence the species name "Eternal ephemera".

.jpg)

_JPG.jpg)

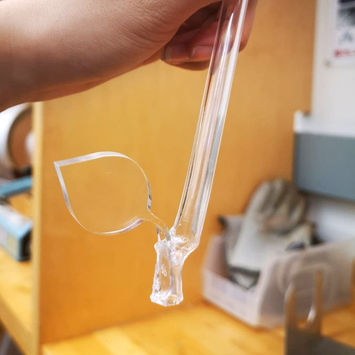

I thermoformed lasercut acrylic sheet by hand to create lifelike leaves. The leaves include cuts that refract light, and push sheet material in a creative way to escape the confines beyond 2D geometry.

I studied and photographed different leaves on my way to class, work, and home. By paying close attention to natural forms, from leaf attachment styles such as palmate, pinnate or compound, to keeping larger leaves near the roots while peppering the canopy with smaller ones, I laid the groundwork to make the plastic look alive, organic.

Observation and Research

Prototyping

I designed new processes to push the limits of what I could do with acrylic sheet, a lasercutter, and a heat gun.

From textile processes of weaving, to twisting, cutting the plastic into strips, I worked to manufacture a plant. I experimented with adhesive, acrylic solvent cement, and heat bonding. I ultimately used a combination of the methods I came up with to better realize my vision.

An exploration in palmate leaves

Material Optimization

I selected an abstract leaf shape with clean curves to show off the dynamic movement of the forming. This shaved off considerable amount of cut time: from 30 seconds per leaf to 5 seconds. This decision increased my working efficiency and made time to iterate more.

I optimized my material efficiency even more by altering the geometry of the leaves: instead of a straight stem as seen in early prototypes, at the suggestion of a course assistant, I created a spiral stem. It lasercut with nearly zero waste, and provided a stem length of up to 5 times using the same sheet of material. This design decision had environmental, cost, and time benefits. I retained some of the spiraled ends at the root base to nod to how they were made.

Acknowledgements

David Beach

Elliot O' Neil Helms

Lee Marom

Dan Somen

Jack Boland

Frank Lou

my coaching group

Alicia Chow

and many others